Attach

We can propose optimal tapes from a wide range of products manufactured by numerous makers. These include structural double-sided tapes that bond materials with strength previously achievable only by adhesives or welding, those complying with VOC regulations, tapes with conductive adhesives, ultra-thin tapes that minimize application space, those with excellent weather and light resistance, tapes usable in high or low temperatures, strong adhesive tapes that are also re-peelable, and tapes strong enough to adhere to difficult-to-bond materials like olefin or soft PVC.

| Material | Feature |

|---|---|

| Double-sided tape for structure | Strength equal to adhesive |

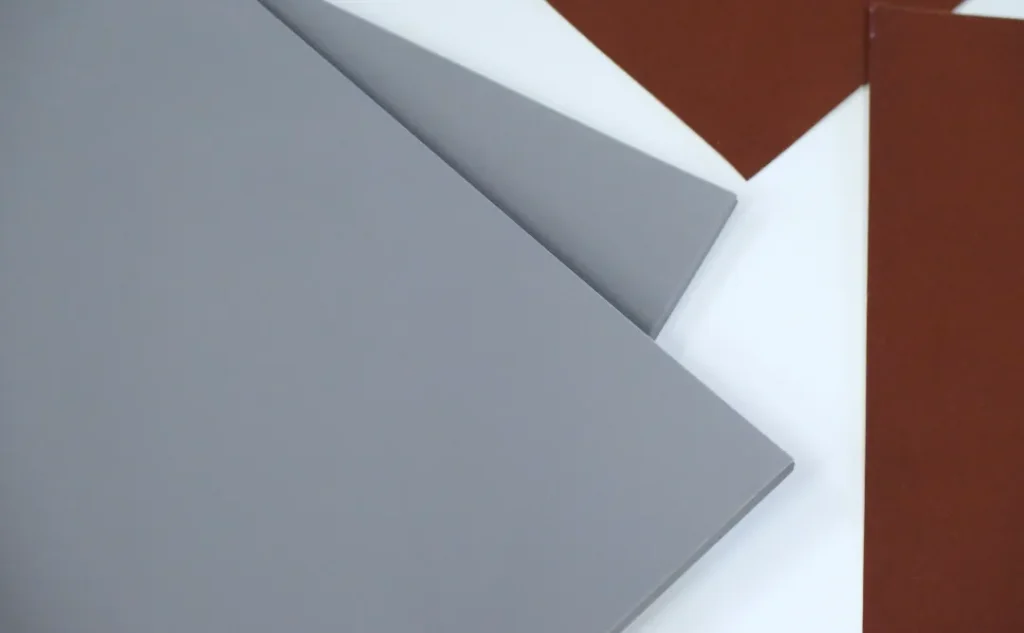

| Material less tape | Thin, Flexibility, Heat resistance |

| Heat resistance double-sided tape | For section to which temperature of 100℃ or higher is applied |

| Conductive double-sided tape | For sections that require conductivity |

| VOC-conforming double-sided tape | Corresponding to the VOC Regulation, No toluene, Emulsion |

| Thin double-sided tape | For adhesion for small devices with less spaces |

| Double-sided tape for exterior | Weather resistance, Heat resistance |

| Incombustible double-sided tape | Conforming to the UL Standard |

| Differential tape | With multiple adhesiveness on one/two surface(s) |

| Double-sided tape for optics | For level difference absorption, High transparency and workability |

| Removable tape | Removable tape for parts recycling |

| Banding tape | For banding of various goods from metal to vegetable |

| Splicing tape | For connecting films or separators |

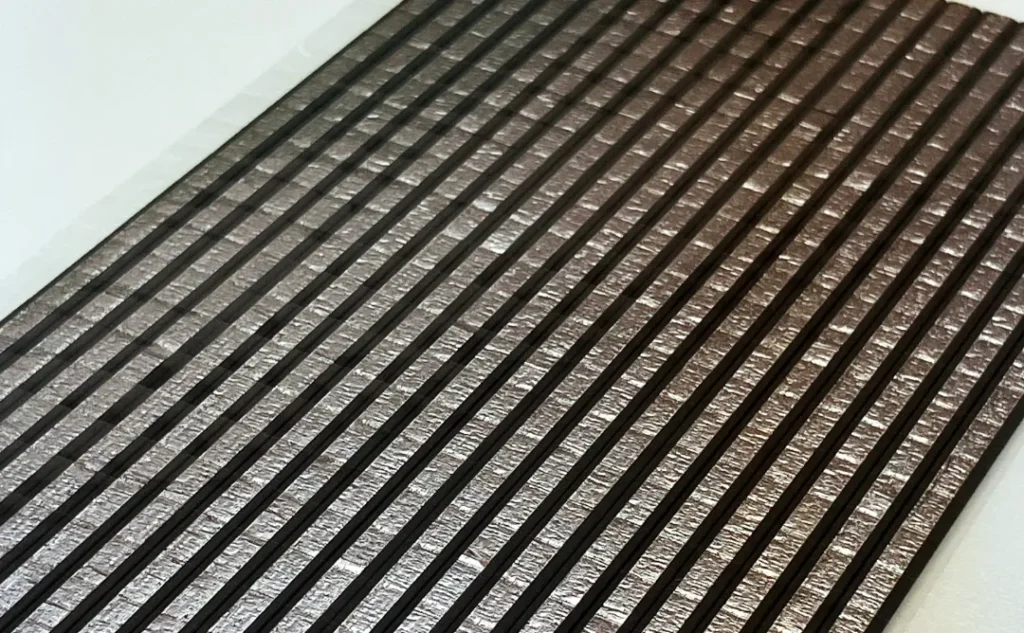

| Double-sided tape for rough surface | For rough surface |

| Plasticizer resistant double-sided tape | Prevent the effect of plasticizer of soft PVC and rubber etc. |

| Double-sided tape for poor adhesiveness | For materials with poor adhesiveness such as silicone and olefin etc. |