Automotive (Drivetrain & Electrical)

Our processed engineering plastics and specialty papers are increasingly being adopted for insulation in lithium-ion batteries and power motors, which are essential for the growing number of hybrid, plug-in hybrid, and electric vehicles (EVs). Furthermore, our materials are widely used for wire harnesses—often called the nervous system of automobiles—in gasoline, EV, and hybrid vehicles alike.

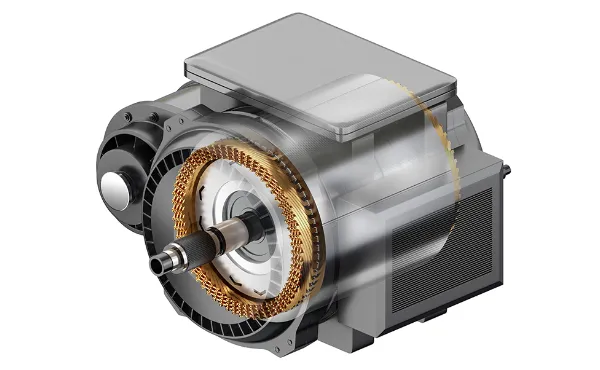

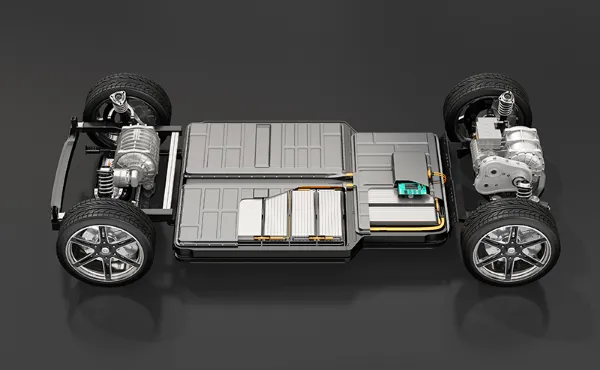

Drive Motors

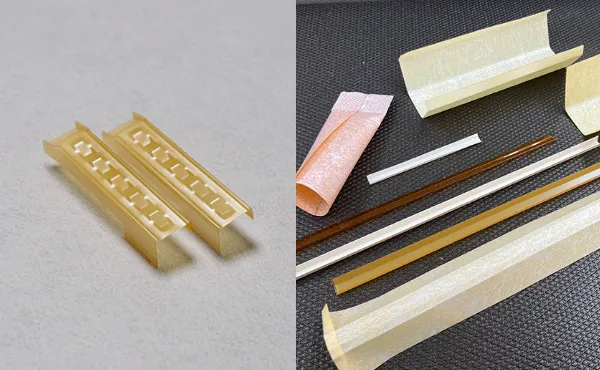

Components Used in EV Motor Stator Cores

These include slot paper to prevent damage when inserting copper wires into the core, and wedge paper to prevent copper wires from popping out. These are cut to the core’s size and then bent. Typically, a three-layer product, consisting of flame-retardant paper sandwiched between high-breakdown voltage and heat-resistant film, is used. We collaborate with major film manufacturers to provide processing support, actively working to get our specifications included in next-generation motors.

Our Products

Our Products

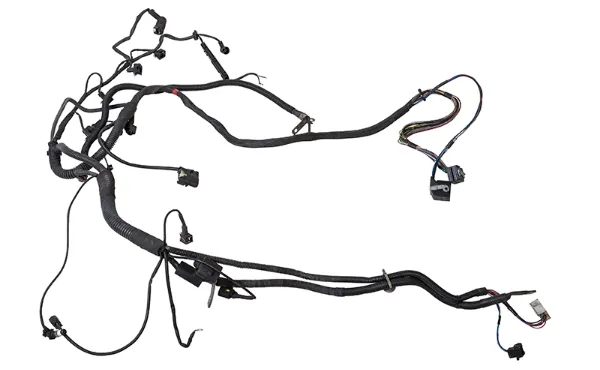

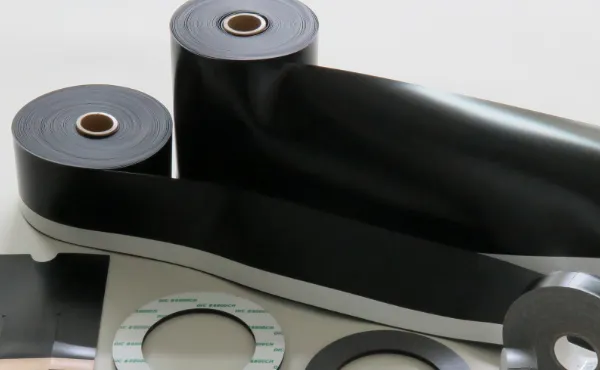

Automotive Wire Harnesses

Soft PVC Protective Materials, PVC Non-Woven Fabric Laminates

Many of our materials are used in wire harnesses, including soft PVC products partially laminated with double-sided tape to protect bundled wires, cushioning sponge materials to prevent harnesses from vibrating and making noise inside the vehicle body, and special die-cut sheets for efficient wire bundling. Notably, our protective sheets are adopted in over 50% of vehicle models in Japan.

Our Products

Our Products

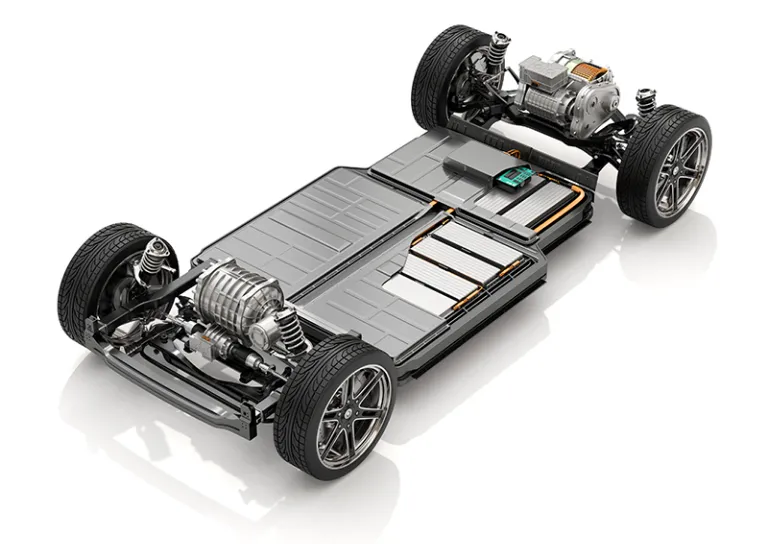

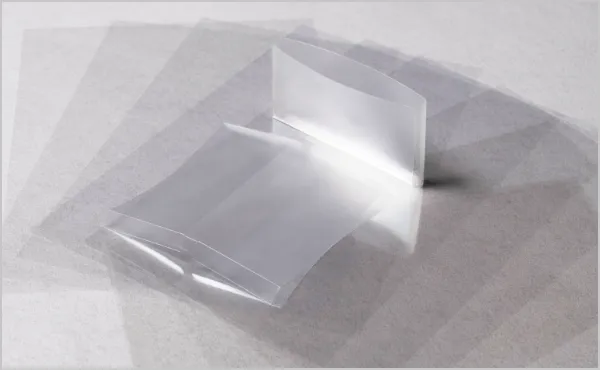

Automotive Batteries

Insulating PP Film

In collaboration with material manufacturers, we have developed a specialized PP (polypropylene) sheet for insulating battery interiors, which we supply to lithium-ion battery manufacturers. This PP sheet offers excellent chemical resistance while maintaining high insulation properties and is treated with an antistatic finish. Furthermore, it undergoes special management for anti-blocking surface treatment and anti-tracking properties.

Our Products

Our Products