Processing Technology

Index

We support diversifying needs for products with high quality, quick delivery and low costs.

We provide the high technical strength to process various materials.

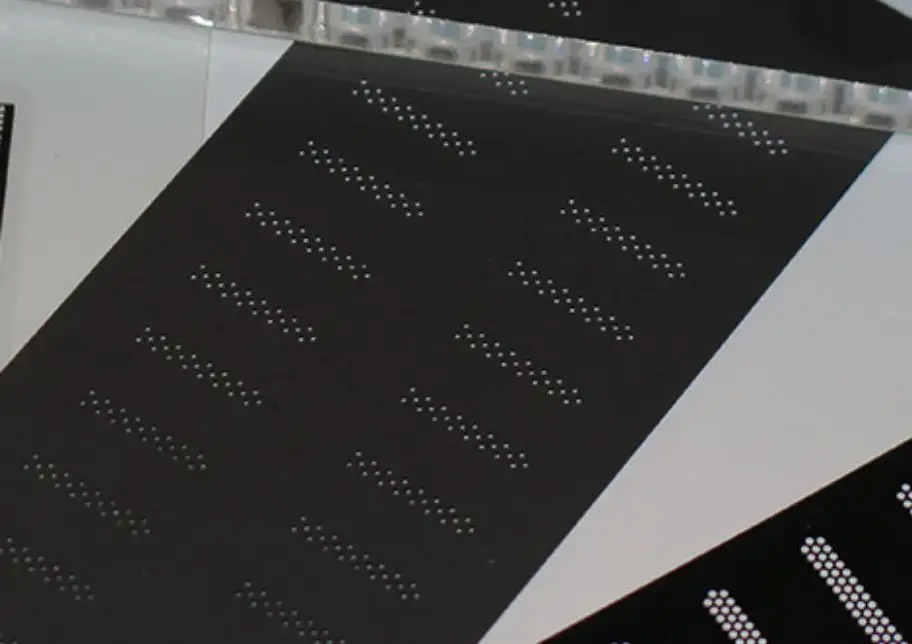

Continuous Punching

When the lot size reaches a certain quantity and we determine that processing with hoop material is more efficient, we perform continuous die-cutting.

Characteristic

- High-Precision Continuous Mass Production Die-Cutting

- High-Precision Continuous Die-Cutting with a 2-Stage Machine

Single Plate Punching

For processing small-lot products or complex, multi-layered components, we utilize press machines that employ hydraulic or servo-crank systems.

Characteristic

- Selection of processing machinery tailored to material properties

- Optimal machine combinations for multi-product, small-lot manufacturing

Extra-Large Punching

We primarily process automotive parts. For this, we own machinery capable of performing full or half cuts on long materials up to 1 meter wide, which was previously impossible. Additionally, we have machines that can punch single parts exceeding 1.5 meters in size.

Characteristic

- Continuous processing of 1m wide roll materials (full and half cuts)

- Super Rotary Die-Cutter capable of handling sizes up to 1.7m square (full cuts)

Combined Processing

Production that enables short lead time by attaching various materials automatically by combining pressing machine and laminator

Characteristic

- Multi-layer lamination for laminates that cannot be laminated manually by combined machines

- Support various patterns from whole surface lamination to precise partial lamination of tapes

- Automatic cutting detection sensor depending on number of products/sheets

Rotary Die-Cutting

For large-lot production, we perform continuous processing using rotary dies.

Characteristic

- High-speed continuous die-cutting using Rotary Die Cut Rolls and Pinnacle Rotary Dies

- High-speed processing of complex shapes with 2-stage machines

Laser Processing

Cutting, punching and engraving of various materials by laser

Characteristic

- Die is not necessary

- It is possible to process various resin materials

- Speedy designing by DXF file

Intoroduction of the Laser Processing Technology

Adhesive Application Robot

We’ve significantly improved work efficiency by using custom-made robots for processes that previously could only be done manually.

Characteristic

- Automation of tasks impossible with standard machinery

- Proprietary designs for processing, tailored to material characteristics and specific operations

Trial Processing

“Internal design/development” to support customer needs

We support from one piece of trial product for various demands by using various molds and jigs

Characteristic

- Support make-to-order production of diversified small-quantity models

- Minimum lead time system by material stock of various kinds and the inspection connected directly from processing

Bending

Can support bending of thick film or strong film that is hard to bend to any angles with a heating bending machine

Characteristic

- Thermal processing that stabilizes bending angles

- Bending angle design by calculating the restoring force based on the abundant experience

- We support minute bending and complicated/multiple bending

Clean Room

Facility whose contamination by airborne particles in air is controlled

Fully equipped clean room (Yamanashi Seimitsu)

Characteristic

- Implement all the processes from material injection, processing to packing in the clean room

- Supports pressing machine and special processing depending on applications

- Air cleanliness standard: FED-STD-209D

- Equipment design: Class 10,000

Other

We support slitting/pasting to desired shapes and other processing of functional materials including various plastic films, optical films and metallic foils etc.

Characteristic

- It is possible to apply various laminates including heat laminate and partial laminate etc.

- We support various demands, from slitting in a normal environment to micro-slitting in a clean room, printing, hot press molding, and combined machining with metal.

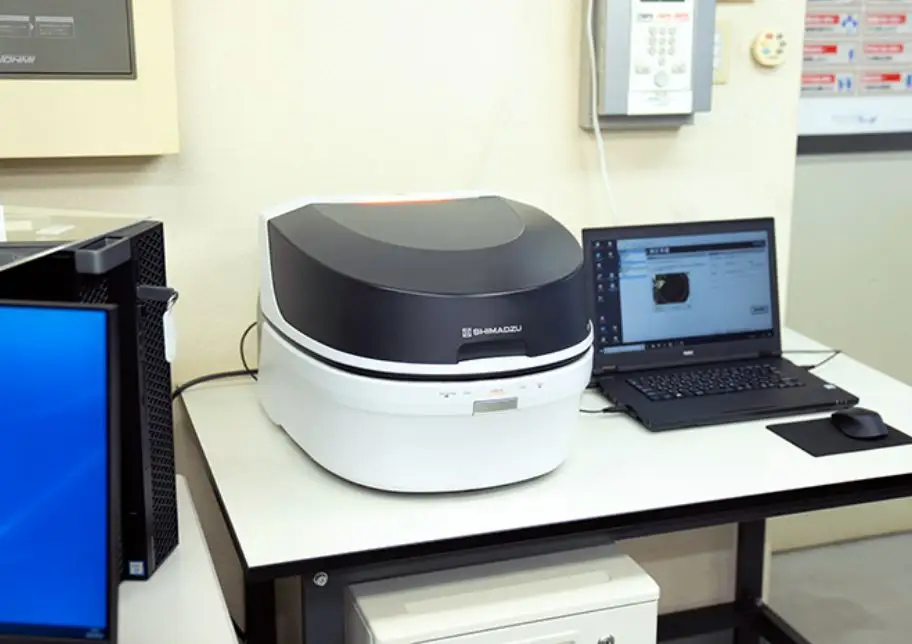

Quality Assurance System

To meet our customers’ needs promptly, we put the utmost effort into ensuring the quality of our products and materials.

Characteristic

- 600 times zoom available, Full automatic measuring by program Image measuring machine and 3D measuring machine are equipped

- X-ray fluorescence spectromer for material composition survey (ROHS)

- Adhesion test (180° peeling test / Tension and compression test)

- Test room whose temperature and humidity are fully controlled

- Quick support various tests

Measuring Equipment

- NC image measuring machine

- 3D measuring machine

- Dispersive X-ray fluorescence spectrometer

- Tension and compression tester

- Projector

- Thermostatic chamber